Polish Patio Covers (7×5 m): Designs, Materials, and Installation Tips

Outline and Why 7×5 m Matters in Poland

A 7×5 m patio cover is large enough to host family dinners yet compact enough to fit most suburban plots. At 35 m², it introduces real structural and planning choices: spans, footing sizes, roofing weight, light transmission, and snow management. In Poland’s temperate climate—with cold winters, gusty transitional seasons, and summer heat waves—getting the details right turns a simple shelter into a reliable, year‑round extension of the home. Think of it as a small outdoor room; comfort, safety, and durability all hinge on design and material decisions that respond to local conditions.

Here’s the outline for what follows, so you can jump to what you need most:

– Planning scope: what 35 m² means for space use, loads, and siting

– Materials and structure: timber, aluminum, steel, and roofing panels or glass

– Design and comfort: roof shapes, orientation, light, and microclimate tweaks

– Installation and approvals: foundations, anchoring, drainage, and paperwork

– Costs, maintenance, and lifecycle: budget ranges, care schedules, and longevity

Why this size? Seven meters often aligns nicely with façade widths, allowing a lean‑to roof to connect between two sturdy points. Five meters offers generous depth for a dining table, grill zone, and circulation, without pushing posts too far into the garden. Yet area adds up quickly: 35 m² multiplied by Polish characteristic ground snow loads (commonly 0.7–1.2 kN/m² in many lowland regions, higher in mountains) yields substantial total forces. Even with a sloped roof that sheds snow, the structure should be checked for partial accumulation. Wind exposure matters too; the cover’s edges and roof overhangs can act like sails if not properly braced.

Function sets the tone. If you want a bright, all‑day space, translucent roofing with carefully placed shading can balance light and heat. If grilling and winter storage top the list, prioritize ventilation, soot‑resistant finishes, and robust gutters. For a quiet reading nook, acoustic comfort and rain‑noise control become important. A well‑planned 7×5 m cover can do all of the above, but clarity early on will guide section sizes, post spacing, and roof form. The rest of this guide translates those aims into practical choices tailored to Polish weather, common plot layouts, and typical building practices.

Materials and Structure: Timber, Aluminum, Steel, and Roofing Choices

Material selection shapes both the look and the lifespan of a patio cover. Timber is warm and forgiving to work with; glued laminated beams handle spans efficiently, and standard planed posts (for example 120×120 mm or 140×140 mm) often suffice for moderate loads when combined with proper bracing. Pressure‑treated softwood is accessible and economical, while hardwood elevates durability and visual appeal. Timber thrives with routine sealing or paint and stainless or hot‑dip galvanized connectors to resist corrosion in Poland’s freeze‑thaw cycles.

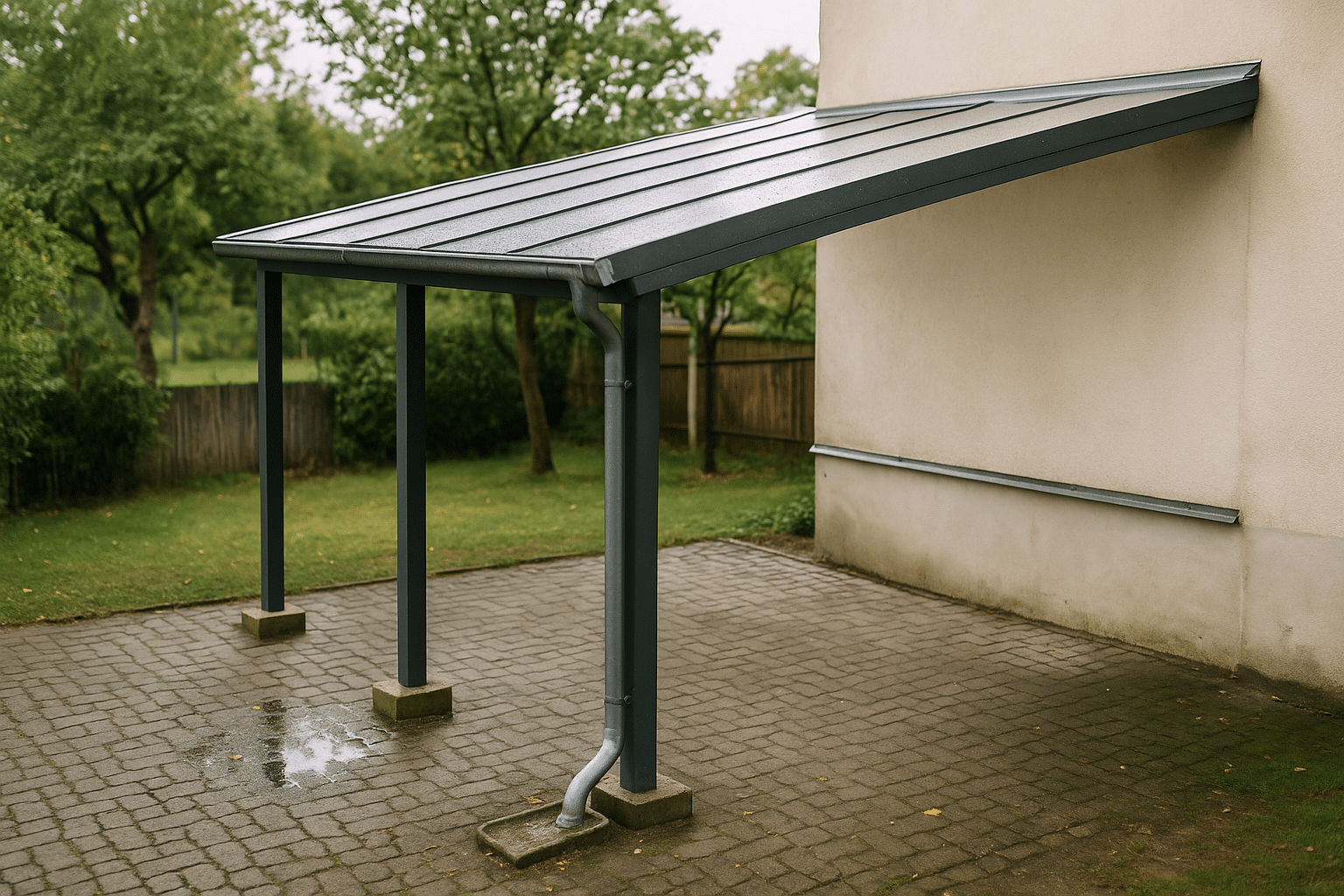

Aluminum frames bring low maintenance and clean lines. Profiles can be sized to carry snow loads with relatively slim members, and powder‑coated finishes handle moisture well. Where salt exposure is low (typical inland), corrosion risk is moderate; near the Baltic coast, mindful specification—sealing cuts, isolating dissimilar metals, and choosing high‑quality coatings—earns dividends. Steel offers high stiffness and slender aesthetics when done right, but it needs consistent protection: hot‑dip galvanizing plus a durable paint system is a practical path for long‑term resilience. In many Polish locales (corrosion category roughly C3 for urban/industrial), careful detailing of drainage holes in hollow sections and avoidance of water traps extend life significantly.

Roofing determines weight, light, and acoustics. Common options include:

– Multiwall polycarbonate: light, impact resistant, translucent; good for daylit spaces

– Solid polycarbonate or laminated glass: clearer views; heavier; quieter in rain

– Metal sheeting: durable, fast to install; higher rain noise; excellent snow slide

– Bitumen or shingles on decking: traditional feel; adds weight; good acoustic damping

For a 7 m span, many designs use a beam along the front edge supported by 3–4 posts, with rafters pitched back to a ledger at the wall. Typical slopes: 5–10 degrees for polymer panels to shed water and snow; at least 2–3% for glass with high‑quality seals. Structural sizing depends on load assumptions: using a characteristic snow load of, say, 0.9 kN/m² and a safety factor appropriate to code, a 35 m² cover could see well over 30 kN distributed load during events, not counting drift. That argues for bracing in both directions, bolted connections, and attention to uplift from wind suction.

Fasteners and connectors should match the base material. For timber: stainless A2/A4 screws in wet areas, galvanized post bases with drainage gaps, and structural bolts where members meet. For aluminum: compatible fasteners with isolation washers to avoid galvanic corrosion. For steel: galvanized or zinc‑flake coated bolts, sealed after assembly. Gutters and downpipes in aluminum or steel are reliable; ensure snow guards or robust panel stops so sliding sheets of snow do not rip fittings away. Good details are quiet guardians: small tweaks like drip edges, back‑flashing at the wall, and compressible gaskets make a big difference over winter after winter.

Design and Comfort: Roof Forms, Orientation, Light, and Ventilation

Form frames experience. A mono‑pitch lean‑to is a popular choice because it ties neatly into a façade and sheds water in one direction. A freestanding gable adds symmetry and airiness, handy when attaching to an insulated or fragile wall is undesirable. Curved rafters with polycarbonate invite softer lines, while a flat frame with a slight fall can suit modern architecture—provided drainage and deflection are carefully controlled. For a 7×5 m footprint, keep the roof plane honest: long, shallow roofs look sleek, but too little slope risks ponding and debris buildup.

Orientation sets mood and energy. South‑facing patios bask in sun, which is welcome in spring and late autumn but can overheat high summer afternoons. East collects breakfast light and sheds heat by evening, while west glows at dinner time and may need shading. North is gentle, even in July, but benefits from translucent roofing to lift brightness. A Polish rule of thumb: plan for a mix—solid shade elements over dining, clear panels near the house to keep interiors bright, and adjustable side screens on the windward edge. Microclimate boosters include a pergola rib along the sunniest band for climbing plants and a low, slatted screen toward prevailing winds to cut gusts without trapping moisture.

Comfort is also acoustic and tactile. Rain on metal is a lively drumbeat; some enjoy it, others prefer the softer hush of polycarbonate or the damped tone of roofing on plywood decking. Snow slide off smooth panels is efficient but can be dramatic; small snow‑stopping trims over high‑traffic edges reduce surprises. Light at night matters too: indirect fixtures mounted under beams avoid glare on clear roofing and prevent reflections back into the house. If electrical conduits run along beams, use UV‑resistant cable channels and grommets where wires pass through metal.

Consider circulation and furnishing clearances. Leave at least 1 m walkways around dining sets, and step the roof height so the outer edge feels open—2.1–2.4 m clear height is comfortable, with higher points near the wall if tying into a façade. Think longevity in little details:

– Integrate a gutter leaf guard to handle autumn drops

– Add a rain barrel connection for plant watering

– Include a hose bib or drain point for easy seasonal cleaning

Finally, style should harmonize with the home. Timber frames stained to match window joinery feel cohesive. Powder‑coated metal in a neutral matte tone sits quietly behind plantings. Transparent edges keep views to orchards or fields, while solid fascia boards hide gutters for a tidy look. Done well, the cover reads like it has always belonged, catching morning light and letting winter’s low sun warm the façade when you most want it.

Installation and Approvals: Foundations, Anchoring, Drainage, and Paperwork

Groundwork starts beneath the frost line. Across much of Poland, foundations should extend roughly 0.8–1.2 m deep depending on region and soil; local guidance and geotechnical conditions prevail. For a 7×5 m cover with a front beam on 3–4 posts, plan individual concrete footings sized to spread loads—common practice might be 350–500 mm square or diameter, thickened below with a bell‑shaped base if soil is weak. Use post bases with adjustable height to fine‑tune alignment and maintain a small gap above paving for drainage and air flow. Concrete quality around C20/25 with reinforcing cages is a practical baseline; protect anchor bolts during pours so threads remain clean.

If attaching to the house, a ledger board must land on structural masonry or a reinforced ring beam, not just insulation or cladding. Through‑bolts with sleeves and chemical anchors make reliable fixings; space them according to the load plan and keep clear of mortar joints where possible. Always flash the ledger: step flashing or a continuous metal flashing tucked under the façade’s weatherproof layer prevents infiltration. At the roof, set slope early with shims or rafter hangers; a 5–10° pitch on polymer panels sheds water and encourages snow slip, while patterned seals and closures keep out wind‑driven drizzle.

Drainage deserves drawings, not guesses. Size gutters for intense summer downpours; for a 35 m² roof, even a short cloudburst can overwhelm undersized outlets. Two downpipes—one on each end—offer redundancy. Direct water away from foundations into a soakaway crate or a raingarden, or harvest it in barrels. Where snow slides are likely, avoid dumping onto stairs or paths; extend downpipes beyond foot‑traffic zones and consider splash blocks.

Paperwork varies with attachment, height, and location. In many cases, small garden structures fall under simplified notification, while larger or attached roofs can require formal permission. Because thresholds and rules evolve, confirm with the local building office (gmina or city) before ordering materials. Bring a simple package: site plan with distances to boundaries, basic elevations, structural notes showing assumed snow and wind loads, and a drainage sketch. A short checklist helps keep you organized:

– Verify property boundaries and underground utilities before digging

– Document neighbor distances; some municipalities set minimum setbacks

– Confirm protection zones (heritage, landscape, utilities) if applicable

– Keep receipts and material specs for inspections

Installation sequence flows smoother with staging: set footings, install posts and front beam, fix ledger, place rafters, add bracing, lay roofing with seals, then gutters and trims. Work safely—temporary props, proper PPE, and weather windows reduce mishaps. In winter regions, schedule roofing on milder days to ensure sealants cure properly. Patience here pays off; the goal is not just a standing structure, but one that stays dry, true, and quiet through many seasons.

Costs, Maintenance, and Lifecycle: Making 35 m² Earn Its Keep

Budgeting a 7×5 m cover in Poland depends on materials, detailing, and labor. As a rough orientation, simple timber frames with polycarbonate roofing might land in the vicinity of 350–700 PLN/m² for materials when self‑built, with labor roughly matching or exceeding materials for contracted work. Powder‑coated aluminum or steel frames can range higher, while laminated glass roofing and intricate trims increase both weight and cost. Custom features—integrated screens, hidden gutters, or sliding panels—add further premiums. Translate that to whole‑project figures and review contingencies: for 35 m², even modest per‑square‑meter shifts move the total substantially.

Operating costs are mostly care and cleaning. Timber needs periodic attention: gentle washing each spring, and re‑oiling or repainting every 2–4 years depending on exposure. Keep an eye on end grain and joint points where water lingers. Metal frames prefer inspection over intervention: look for scratches in coatings, touch up promptly, and clear debris from hollow profiles. Polycarbonate responds well to soft‑cloth cleaning with mild soap; avoid solvents that craze the surface. Glass benefits from hydrophilic coatings but can be maintained with squeegees and seasonal rinses.

Small habits extend life:

– Brush leaves from gutters before winter

– Check fasteners annually, tightening where timber has seasoned

– Inspect seals and flashing after heavy storms

– Clear heavy snow in safe increments if drifts accumulate near the wall

Think lifecycle beyond parts. A well‑detailed cover reduces maintenance on paving and furniture below, protects door thresholds from splashback, and can temper interior temperatures by shading façades in summer. It can also store value: outdoor living spaces are attractive to many buyers, especially when execution looks intentional and drainage, lighting, and finishes match the home. Sustainability gains are within reach—use certified timber, capture rainwater for the garden, and choose durable, repairable components. If panels must be replaced after a long service life, select materials with established recycling routes.

Finally, keep perspective with a simple plan: a five‑year calendar for coatings, an annual hour each spring for fasteners and gutters, and a mid‑winter glance after the first wet snow. Those small rituals keep the 7×5 m cover feeling fresh and sturdy. Over time, patina becomes part of the charm: timber deepens in tone, metal settles into its matte sheen, and the roof’s fine scratches hold memories of seasons well spent. That’s the quiet payoff—an outdoor room that earns its place by working hard and aging gracefully.