Factors to Consider When Choosing Carbon Steel Sheets

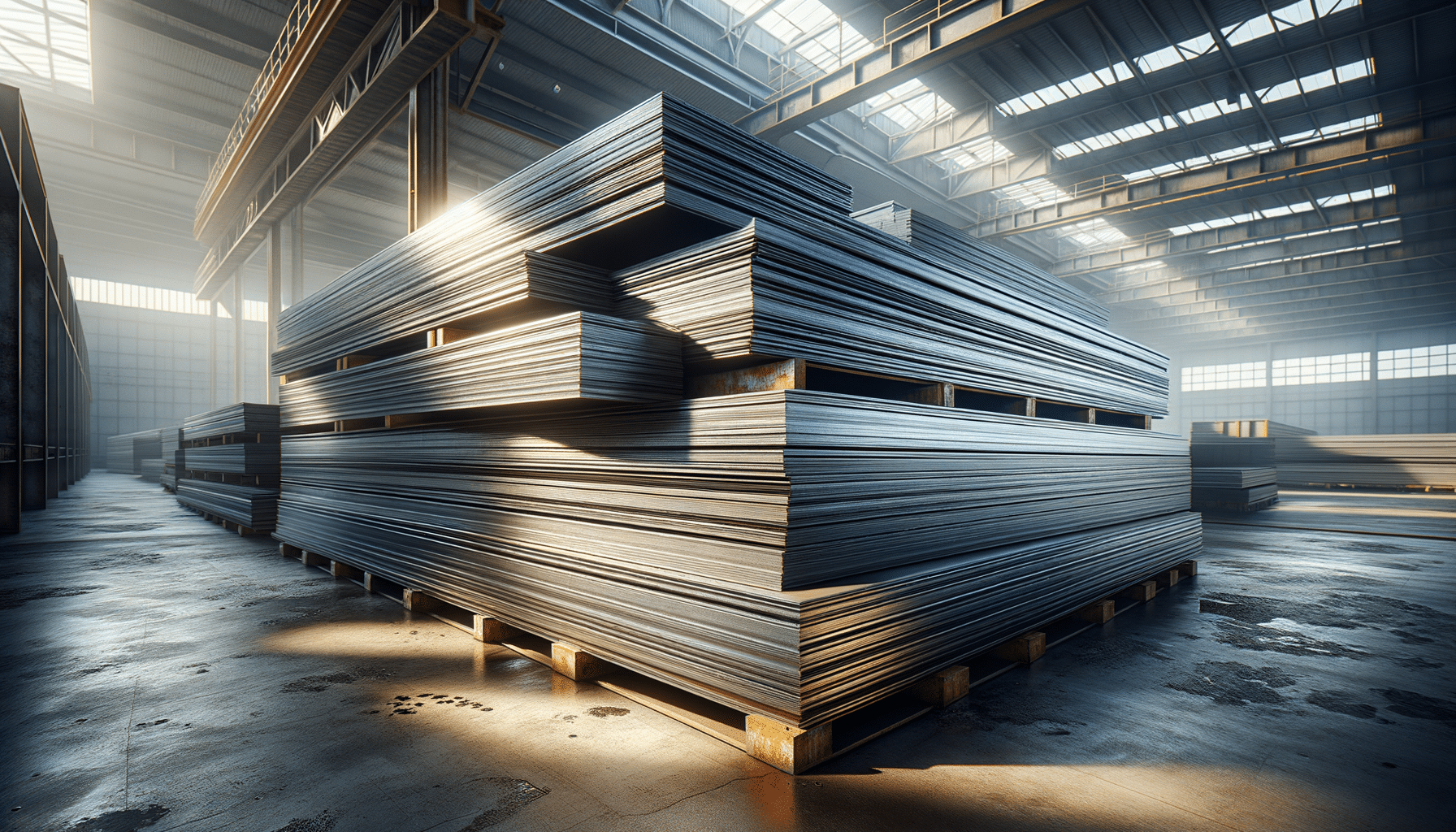

Introduction to Carbon Steel Sheets

Carbon steel sheets are an integral component in many industries, offering versatility and strength. Their usage spans from construction to automotive manufacturing, making them a fundamental material for various applications. Understanding the properties of carbon steel sheets is essential for anyone looking to choose the right type for their project. These sheets are known for their durability and ability to withstand significant stress, making them a prime choice for structural applications.

One of the key factors that make carbon steel sheets so widely used is their affordability compared to other metal options. They provide a cost-effective solution without compromising on quality or performance. Additionally, the ease of fabrication and welding adds to their appeal, allowing for seamless integration into existing structures or new designs.

Types of Carbon Steel Sheets

Carbon steel sheets come in various types, each offering unique properties suited to specific applications. The three primary categories are low carbon, medium carbon, and high carbon steel sheets. Low carbon steel sheets are known for their ductility and ease of machining, making them ideal for applications requiring intricate shapes or designs. They are often used in the automotive industry for body panels and other components.

Medium carbon steel sheets offer a balance between strength and ductility, making them suitable for structural applications. They are commonly used in the construction industry for beams, frames, and other load-bearing structures. High carbon steel sheets, on the other hand, provide exceptional hardness and strength, making them ideal for cutting tools and high-stress applications.

Factors to Consider When Selecting Carbon Steel Sheets

When choosing carbon steel sheets, several factors must be considered to ensure the material meets the project’s specific requirements. The first consideration is the application’s environment. For instance, if the sheets will be exposed to corrosive elements, opting for a type with better resistance, such as galvanized carbon steel, might be necessary.

Another critical factor is the required strength and hardness. Depending on the load and stress the material will face, selecting the appropriate type of carbon steel sheet is crucial. Additionally, the ease of fabrication and welding should be considered, especially for projects requiring custom shapes or sizes.

- Corrosion resistance

- Strength and hardness

- Fabrication and welding ease

Applications of Carbon Steel Sheets

Carbon steel sheets are used in a myriad of applications across various industries. In the construction sector, they are essential for creating durable and reliable structures. Their ability to withstand significant loads makes them ideal for beams, frames, and other architectural elements. In the automotive industry, carbon steel sheets are used for body panels, chassis, and other components that require a balance of strength and ductility.

The manufacturing sector also heavily relies on carbon steel sheets for producing machinery and equipment. Their versatility allows for the creation of complex shapes and designs, making them indispensable for producing a wide range of products.

Conclusion: Making the Right Choice

Selecting the right carbon steel sheets is crucial for the success of any project. By understanding the different types available and considering factors such as environment, strength, and fabrication needs, one can make an informed decision that ensures the material will perform effectively over time. Whether for construction, manufacturing, or automotive applications, carbon steel sheets offer a reliable and cost-effective solution.